Virtual Reality (VR) technology has revolutionized the way we interact with digital content, immersing users in captivating virtual environments. Behind the scenes, various materials and technologies contribute to the functionality and comfort of VR equipment. One such material gaining prominence in the development of VR devices is TPU (Thermoplastic Polyurethane). In this article, we'll explore how TPU for VR equipment works and the benefits it brings to the immersive experience.

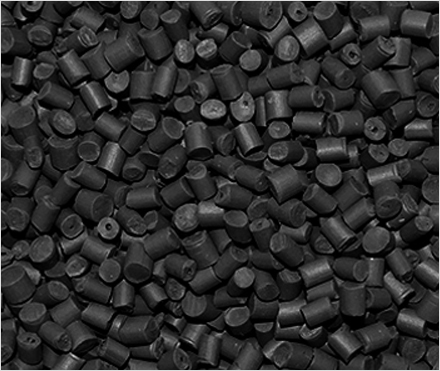

Thermoplastic Polyurethane (TPU) is a versatile polymer known for its elasticity, durability, and resistance to abrasion. It is created through the reaction of diisocyanates with polyols, resulting in a material that combines the flexibility of rubber with the processability of thermoplastics. TPU is widely used in various industries, including consumer electronics, automotive, and medical devices, due to its unique properties.

Comfortable Fit: One of the key factors influencing the VR experience is comfort, especially during extended use. TPU's flexibility allows for the creation of soft and pliable components, such as headbands and cushioning pads, which conform to the user's head shape and provide a comfortable fit. This minimizes pressure points and discomfort, enabling users to enjoy immersive VR experiences for longer durations.

Durable Construction: VR equipment is often subjected to frequent handling and movement, necessitating materials that can withstand wear and tear. TPU's high abrasion resistance makes it an ideal choice for protective components, ensuring the longevity of VR headsets and accessories. Whether it's the outer shell of a headset or the connectors of a controller, TPU enhances the durability of VR equipment, resulting in products that withstand the rigors of daily use.

Flexibility and Adaptability: VR equipment requires components that can accommodate a wide range of user preferences and head sizes. TPU's elasticity allows for the creation of adjustable straps and flexible hinges that adapt to various head shapes and sizes. This versatility ensures a snug and secure fit for users, enhancing immersion and preventing distractions during VR experiences.

Impact Resistance: Accidental drops or impacts can pose a threat to the integrity of VR equipment, potentially leading to damage or malfunction. TPU's impact resistance helps mitigate these risks by providing a protective barrier against external forces. Whether it's a headset falling off a table or a controller slipping from the user's grasp, TPU components offer an added layer of protection, safeguarding the device's internal components and prolonging its lifespan.

Incorporating TPU into VR equipment design offers a multitude of benefits, ranging from enhanced comfort and durability to improved flexibility and impact resistance. By leveraging the unique properties of TPU, manufacturers can create VR devices that deliver an immersive and enjoyable experience for users while ensuring reliability and longevity. As VR technology continues to evolve, TPU is poised to play a significant role in shaping the future of virtual reality, providing the foundation for innovative and immersive experiences.