In today's digital age, cables play a crucial role in connecting various devices and networks, enabling smooth communication and data transfer processes. As technology advances rapidly, the demand for more durable and reliable cables is on the rise. One such material that has gained popularity in the cable manufacturing industry is TPU (Thermoplastic Polyurethane) cable jacket material. In this blog, we will explore the role of TPU material in ensuring cable safety and longevity.

TPU, a versatile polymer, is known for its excellent mechanical properties, making it an ideal choice for cable jacketing. It provides a combination of flexibility, toughness, abrasion resistance, and chemical resistance. This material has outstanding resistance to oil, solvents, and UV radiation, making it suitable for a wide range of applications. Its ability to withstand extreme temperatures makes TPU cable jacket material a reliable choice even in harsh environmental conditions.

Safety is a critical aspect when it comes to cables, especially in applications where they are exposed to potential hazards. TPU cable jacket material offers remarkable electrical insulation properties, ensuring the safety of both the cable and the surrounding environment. It effectively protects the conductors from external factors like moisture, heat, and physical damage, preventing short circuits, electric shocks, and fire hazards.

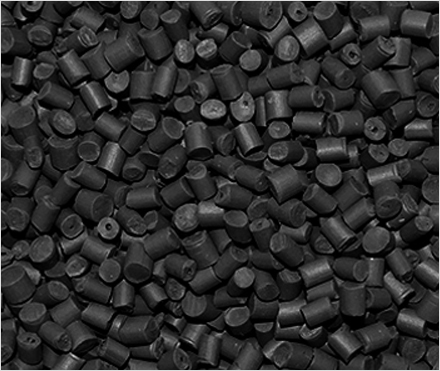

ATP company has various types of TPU cable jacket materials for sale which you can choose from:

(1) Anti-static TPU

(5) Easy Peeling/Strip Off TPU

Cable longevity is directly linked to its durability and resistance to wear and tear. TPU material possesses exceptional abrasion resistance, which extends the lifespan of cables. It can withstand repeated bending, flexing, and stretching without losing its shape or mechanical properties. This not only reduces the chances of cable failure but also minimizes maintenance and replacement costs, making it a cost-effective choice for various industries.

TPU material offers a high degree of customization and versatility. It can be easily tailored to meet specific requirements, such as color coding, branding, or specialized applications. TPU cable jacket material, like biological compatibility TPU, is available in different grades, allowing manufacturers to choose the optimum formulation for their specific cable needs. Additionally, it is compatible with various cable manufacturing processes, including extrusion and injection molding.

In an era where connectivity is essential, cables must be reliable, durable, and safe. TPU cable jacket material stands out as an excellent choice for ensuring cable safety and longevity. Its unique combination of mechanical properties, electrical insulation, abrasion resistance, and customization options make it a preferred material for diverse industries. As technology continues to advance, TPU is likely to play an increasingly crucial role in the evolution of high-quality cables that meet the demands of our connected world.