In today's safety-conscious industrial landscape, Low Smoke Zero Halogen (LSZH) cable applications have emerged as a critical solution for environments where human safety and environmental protection are paramount. ATP Polymer Technology Co., Ltd., as a pioneer in high-performance polymer compounds, specializes in advanced LSZH materials that meet the most stringent international standards while maintaining excellent electrical and mechanical properties.

Unlike traditional PVC-based cables, LSZH cables produce minimal smoke and toxic fumes when exposed to fire, making them indispensable in public transport systems, underground installations, and confined spaces. With 12,000 tons of annual production capacity and CNAS-certified R&D capabilities, ATP delivers cutting-edge Thermoplastic LSZH formulations for industrial cables that combine flame retardancy with superior processing characteristics.

The superiority of LSZH in cable applications stems from its unique material composition designed for safety without compromising performance. ATP's LSZH compounds offer:

Ultra-low smoke emission (reducing visibility obstruction during fires).

Zero halogen content (eliminating toxic acid gas formation).

High flame retardancy (complying with EU CPR & GB31247 standards).

Flexibility & durability (suitable for dynamic cable applications).

Environmental sustainability (free from restricted substances under RoHS & REACH).

These properties make LSZH cable applications ideal for metro systems, data centers, hospitals, and marine installations, where human life and sensitive equipment must be protected from fire risks.

ATP's thermoplastic LSZH cables serve a diverse range of industries, including:

Rail & Metro Systems

Fire-resistant power and control cabling.

Minimized smoke in tunnels and enclosed carriages.

Building & Infrastructure

Commercial complexes & high-rises (complying with strict fire safety codes).

Smart buildings & IoT wiring (ensuring minimal toxic emissions).

Renewable Energy & Power Transmission.

Solar farms & wind turbine cabling (with UV and weather-resistant properties).

Substation and underground power distribution (enhanced fire safety).

Military & Aerospace

Lightweight, flame-retardant cables for aircraft & defense applications

The adaptability of LSZH cable applications proves that safety and performance can coexist, setting new benchmarks in industrial cabling.

While standard PVC (Polyvinyl Chloride) and XLPE (Cross-linked Polyethylene) cables dominate general electrical applications, LSZH cables provide superior safety features, as illustrated below:

Property | LSZH Cables | PVC Cables | XLPE Cables |

Smoke Emission | Extremely low | High | Moderate |

Toxic Gas Release | None (halogen-free) | High (HCl gas) | Low (but still present) |

Flame Resistance | Excellent (self-extinguishing) | Poor (supports combustion) | Moderate (requires additives) |

Flexibility & Durability | High (depends on formulation) | Very flexible | Stiffer than LSZH |

Environmental Impact | Fully RoHS-compliant | Contains plasticizers | Thermoset (non-recyclable) |

ATP's thermoplastic LSZH cables outperform PVC and XLPE in fire safety, proving essential for high-risk installations like subways and hospitals.

With the growing emphasis on sustainability and fire safety regulations, LSZH cable applications are evolving to meet new industry demands, including:

Halogen-free flame-retardant grades for 5G and telecom networks.

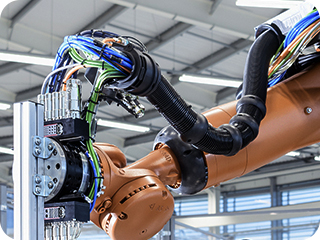

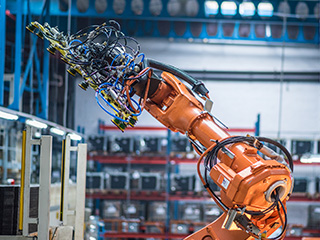

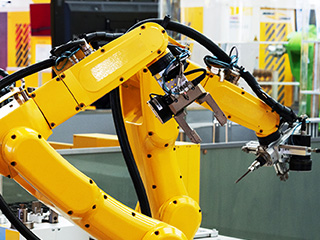

Ultra-flexible LSZH for robotics and automated machinery.

Bio-based LSZH materials for eco-conscious projects.

ATP's commitment to cutting-edge R&D ensures their LSZH compounds remain at the forefront of polymer innovation, reinforcing LSZH as the cable material of the future.

LSZH cable applications represent a technological leap in polymer safety, offering zero-toxicity, minimal smoke, and superior flame resistance—qualities that traditional cables struggle to match. As industries worldwide shift toward stricter fire safety regulations, ATP Polymer Technology Co., Ltd. leads the charge with high-performance LSZH solutions that guarantee compliance, durability, and sustainability.

With LSZH becoming mandatory in many infrastructure projects, ATP's expertise in thermoplastic polymer materials for industrial cables ensures that safety and innovation go hand in hand, cementing LSZH as the gold standard in critical applications.